Products

Nano Technology

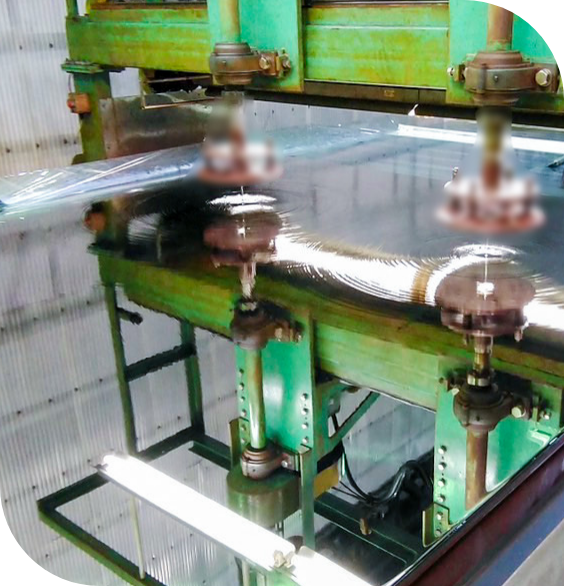

Super Mirror Grinding

Our Nano technology provides excellent mirror surface finish and minimizes its surface to several nanometers.

This mirror surface finish have better functionality than traditional mirror surface.

We achieved our unique technology upto ultra precise level which can be

proved only by optical microscope, which are expected to enter in a new fields, including other metals alternative to rare metals and enlargement of the LCD in the future.

EN1,4301/AISI304 2B

Sheet SuperMirrorGrindin

EN1,4303/AISI305 1/2H

Coil Hoop SuperMirrorGrinding

Hot-rolled titanium

EGR + SuperMirrorGrinding

Technology

Various techniques for polishing of titanium such as mechanical, chemical, electrolytic and electrolytic-abrasive polishing and so on have been outlined.

Recently the titanium sheet with the average surface roughness (Ra) of nanometer-order has been obtained by using the mechanical and the electrolytic-abrasive polishing processes with comparative ease. The mirror polished titanium has served various uses from the artistic production to the high technology field e.g.

as MEMS devices. In case of complex parts as the dental and the medical treatments, the electrolytic polishing is preferably applied. It is important that the polishing technique should be selected with the shape and size of the work

Ability

- Thickness

- 0.3mm or more(Sheet)

0.3mm~0.5mm(Coil Hoop)

- Width x Length

- 300mm~3000mm x 300mm~14000mm(Sheet)

300mm~1219mm x Coil (Coil Hoop)

- Surface Roughness

- Stainless Steel – 1~5nm

Pure Titanium and Titanium Alloys – 5~6nm

Aluminum Alloys – 4~5nm

*Coil hoops are only available for stainless steel